Category: News

CO²e Bilanz 2023 – Scope 1 & Scope 2

We take our responsibility for our environment seriously and have prepared our CO²e report for 2023 using the “ecocockpit” tool from EFFIZIENZ-AGENTUR NRW.

In this report, we look at direct emissions according to Scope 1 and indirect emissions according to Scope 2.

We will compile the indirect emissions according to Scope 3 step by step.

The direct emissions according to Scope 1 are the purchase of energy sources for internal combustion: fossil fuels such as gas, oil, diesel, petrol for heating and for business trips with company-owned vehicles.

Indirect emissions according to Scope 2 represent the purchase of energy sources such as electricity and district heating.

We work with our suppliers and partners to determine the indirect emissions according to Scope 3, which include the purchase of services and products from third parties, and will successively determine and report these values.

Our aim is to continuously reduce our CO²e emissions. This report is the basis for evaluating our progress for future reporting periods.

Certification audit passed successfully

On August 22nd, 2024, we have successfully passed the certification audit for DIN EN ISO 9001:2015 and DIN EN ISO 14001:2015.

All certificates can be downloaded with the following link:

Congratulations

Our apprentice tool mechanic – mold technology Mr. Yannik Sinner passed the intermediate examination with flying colors!

The evaluated areas:

Work tasks with situational discussion phases, written tasks and the complex work task were each completed with “sehr gut“- outstanding result!

Congratulations from the head of our toolmaking department, Mr. Welder, and the entire team at BILORA Kunststofftechnik.

Welcome Mr. Steffen

We welcome Mr. Torsten Steffen, who will be joining our team as Head of Quality Assurance.

Mr. Steffen is succeeding Mr. Boxberg, who has gone into well-deserved retirement.

At this point, we would like to say a big thank you to Mr. Boxberg for his many years of support for our company and wish him all the best, especially good health, for his retirement.

As a state-certified technician in the field of mechanical engineering and production technology, Mr. Steffen comes to us with more than 25 years of experience in quality assurance.

We look forward to a successful collaboration.

Injection molding

After extensive renovation work, the injection molding production has a new appearance.

Welcome Mr. Naumann

We welcome Mr. Marcel Naumann, who will support our team in the areas of project management and sales.

Mr. Naumann will be your BILORA contact person for current and new projects. As a tool mechanic and state-certified technician in the field of mechanical engineering, he has extensive experience both in the implementation of customer requirements into a product and in plastic injection moulding and the associated tool and production technology.

All in the spirit of: Molding your standard.

We look forward to a successful collaboration.

Donations instead of gifts

Extension of production capacity

In order to be able to meet the increasing demand, we have invested in two new injection molding machines with a clamping force of 2,400kN and 1,800kN.

Both machines work extremely efficiently and use only about 50% of the energy compared to conventional injection molding machines.

BILORA on tour

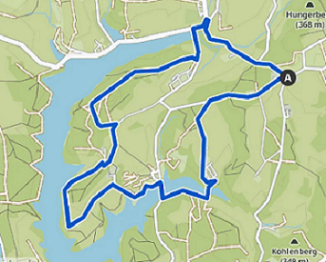

On May 6th, 2023, the annual BILORA Hiking Day took place. After coffee and cake, we started in Egen. Via a circular route, along the Bevertalsperre, we reached our starting point after 8 km and 130 meters of altitude.

The hikers and none hikers met in the Gasthaus Wigger for dinner.